Secondary Construction

Went to

my FAV store, Home Depot, and picked up a few goodies. I was looking to build a

simple secondary winder on a micro-budget. Here's what I managed to snag...

1) 36" Length of AL rod.

2) Two rolls of AL tape (eventually to be

used on my toroid....or not. Just wanted more than I had).

3) 4 4" I.D. PVC

endcaps (I really only needed two, but what the heck).

4) Probably the most

unusual, but nessecary. Nabbed a cheapie $6 toilet snake for the crank. I just

hacksawed off the snake part, and voila! Instant crank!

I had a lot of

scrap wood laying about the garage from remodeling my house, so for the base I

just used some 2x6. Nothing fancy here!

Here's the

setup...see the wood thing under the spool of wire? That was what I was going to

cradle the spool in for winding, but the tension was hellacious! So, I drilled a

few holes into the studs & threw an aluminum rod in there. I chose AL stuff

because....

1) It bends easily. So if I fork up an alignment hole,

no biggie. I can live with a little wobble.

2) It's a lot cheaper

than steel!

Closeup of my 8 Cyl mega-winder! Fully blown with an

oversized CAM and performance valves! =)

O.K., O.K., it's only the

aforementioned crank duct-taped to the top PVC cap. The head in the background

came in handy for holding my work as I drilled or sawed! Note the wood shim in

the shaft hole for tension...

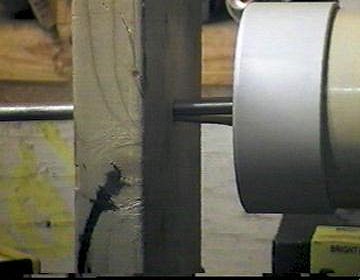

Another close-up of

the duct-tape junction

The stationary AL rod side, also shimmed.

Another shot of the whole works...

O.K., I'm having WAY too much fun winding this secondary...note the beer fridge off to the left!

Looks like the secondary passed the OFISC (Objective

Feline Inspection of Secondary Construction) test. Here's 'Mando' checking out

the specs...this is the closest he's ever going to get to this baby!

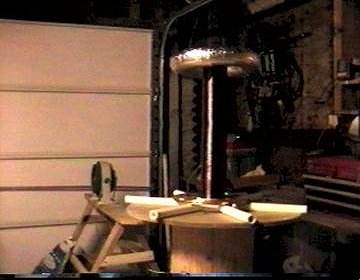

A shot of the finished secondary, caked in PU, and topped off with the

ubiquitous "dryer-vent" toroid. It's just resting on top of the secondary for

the sake of a more impressive (?) shot. The primary supports aren't the finished

deal either. Too many alignment problems (drilling round stock is an absolute

P.I.T.A.!). I'm opting for a diced plastic kitchen cutting board for primary

supports. Looks better with the sexy tabletop provided by Jim and the crew at

Ladco, too. Nabbed some cable reels from Sembert Pallet & Lumber of Model

City, NY (What About Bob?) for support. I'm still tinkering on how to go about

incorporating these into my final design.

And here are a few shots of that aforementioned sexy

tabletop, courtesy of Ladco Displays of Canada.

Check out

the ham, Nikko the Cat, chillin' like a villan in the chair behind the

tabletop...

How sweet is this???

This is an

absolute work of CNC art!!! I only hope that I can do it justice in my final

design. Check out the 6 slots for added tuning capability, perfectly machined

from 1"x30" acrylic. Esthetic beauty, as well as electrical insulation.

Back to

Home Page!