MMC Tesla coil capacitors have become almost the standard TC capacitor in less than a year. They are very reliable, inexpensive, easy to make, and have no oil. Basically, they are made by stringing many small commercial polypropylene capacitors together the form a larger capacitor that can withstand the high voltage and high current of Tesla coils. MMCs have been extensively studied and characterized in TC applications.

I like to use Panasonic ECW-H 16563JV 1600VDC 0.056uF Polypropylene caps from DigiKey (# P10516-ND) but many other brands work too. They have to be metalized polypropylene types rated for around 1500 volts. We have found that the DC voltage rating can be used as the peak AC voltage rating. In fact "I" like to push their voltage beyond those ratings a bit to save money. The caps are very tough and can withstand about 3000 volts in testing.

This document explains how the power handling is calculated and this program will do the calculations and design for you.

Here is the known

GOOD caps and known BAD caps list!

Here are the essential tips in building them:

1. Always make the strings individually

selectable so you can get many

different values of capacitance.

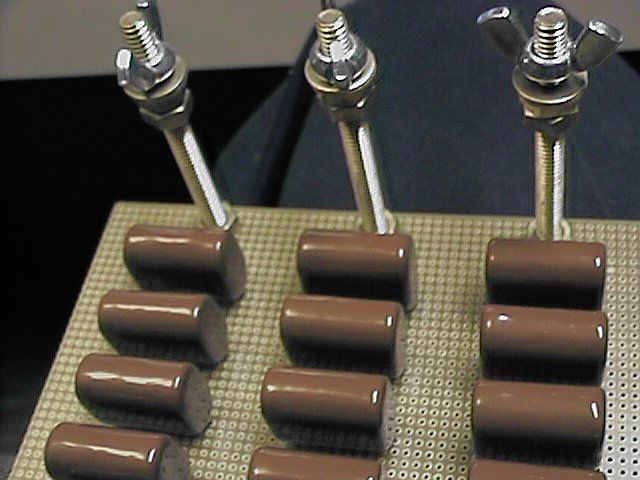

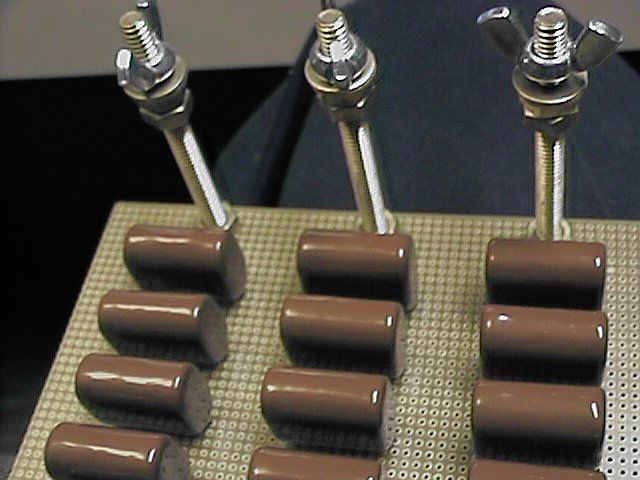

2. Leave a small (~1/8")air space

in between the caps in a string for

air flow and to leave room

if one fails.

3. Be sure to leave a good distance

(~1" or more) between the strings

so if some are not used,

that active strings will not arc to inactive strings.

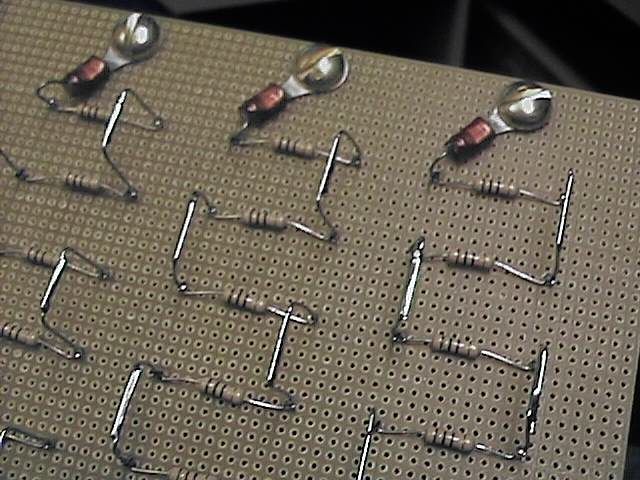

4. Put 1/2W 10Meg ohm (or some close

value) resistors across each cap for

safety and balancing.*

4.1 Do not place the resistors directly against the capacitors! The thin capacitor shell may not provide good insulation. The capacitors need a good space between them and other objects to insure they will not arc over. I would recommend about 1/4 inch clearance between the capacitor cases and other things.

5. Be sure the resister leads are

actually wrapped around the cap leads

so they will stay in place

if the solder gets hot or the solder connection

was not sound.*

6. Remember that the whole cap is

at very high voltage so it needs to be

mounted away from metal and

in a safe location.

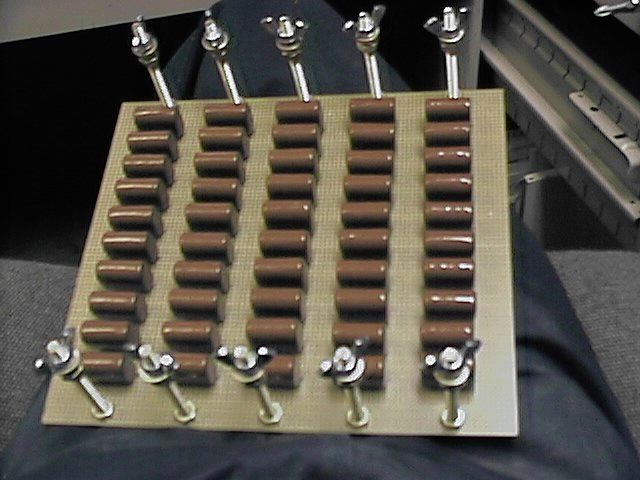

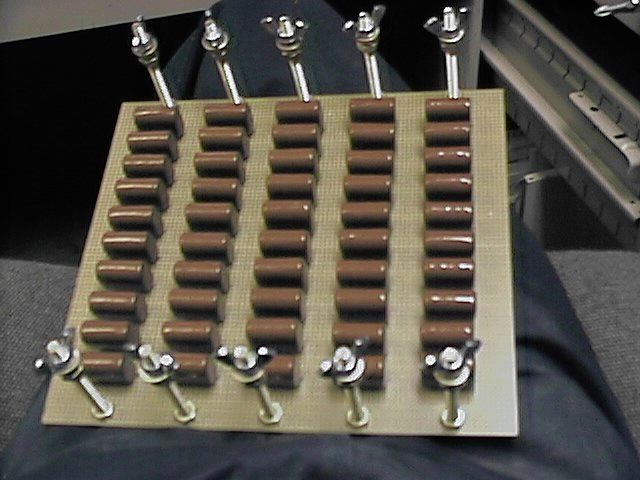

7. Perfboard, like DigiKey# V1011-ND, makes mounting the caps really easy.

7.1 Be careful when bending the leads not to damage the connections inside the capacitor. Tubular style caps can especially have fragile lead connections.

8. Do not connect the caps between

strings together even though they are

at the same potential.

This defeats the cap's self healing and value

selection features.

9. Even though the cap leads seem

small, use heavy primary wiring and try

to use brass or copper connections

as with any Tesla cap. Bringing the ends

of each string to 1/4" brass

bolts works well.

10. Remember that even a small EMMC

cap can be just as dangerous as many

big oil filled caps...

The resistors go a very long way in making them safer

but don't get careless.

* People have gotten shocked by

not doing these.

Here are some other papers on poly caps:

LT POWER CAPACITORS - Trends in Technology and Review of Performance

The Development and Performance

of High Reliability, High Energy Density Pulsed Discharge Capacitors

OneTwoThreeFourFiveSix

Here are a bunch of PDF files about poly caps from the manufacturers

Here are some early

pics from my first MMC cap testing on November 12 of 1998.