|

|

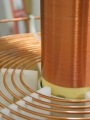

I wound the secondary on a length of 80mm PVC

drainpipe from Mr Mitre10, my local hardware emporium.

I'd had a look around for suitable secondary formers I

might be able to scavenge and all the ones I came across

in skips and so on were really beaten up and manky, so I

thought I'd go with a brand new fresh piece. Of course it

comes in 3m lengths and you can't buy just the bit you

want, but it wasn't too expensive. I had to remember

to take along a hacksaw so I could get it home though - I

can't fit 3 metres of anything in my car. Drainpipe's not

heavy, I suppose I could've walked it back. But people

look at me funny already.

I cut it to length, sanded off the lettering printed

along it, fitted it into my rudimentary winding jig and

gave it a coat of polyurethane varnish. The winding

itself was done with 0.4mm diameter magnet wire, for a

wound length of about 520mm - so I guess there are

approximately 1300 turns. Once the secondary was wound it

had another 2 or 3 coats of polyurethane (still on the

winding jig, so I could continue turning it as it dried

and prevent too many aesthetically displeasing drips or

runs in the coating)

The secondary's mounted in the closest-fitting pipe

endcap I could find, which is bolted down to the

baseboard of the coil. The endcap didn't really fit the

drainpipe all that well, so I epoxied some wedge-shaped

pieces of perspex to the sides of the secondary former to

make for a tighter fit. I also fitted a long nylon bolt

that passes through holes in the side walls of the endcap

and the bottom of the secondary former and stops the

secondary from lifting out.

|

|

![]() DC Coil

Secondary Winding

DC Coil

Secondary Winding