The "Twins"

(A chronicle)

| 8ft White Hot Arcs (1,115KB) | Click Here To View |

| The Elusive 10ft-ers (1,284KB) | Click Here To View |

First Light July 8, 2002

The Twins were not working together at all. Racing sparks up and down each side, and sparks not attracted to each other.

Second Light July 13 2002

After an attitude adjustment (actually an altitude adjustment for each secondary of +3-in), and a change in Twin2 primary wiring, the racing sparks ended and the Twins started co-operating.

Longest Sparks (Toroid-to-Toroid 8ft)

Specifications:

| Input Voltage Measured (VAC) | 237 |

| Input Current Measured (A) | 103 |

| Output Voltage (VAC) | 14400 |

| Inside Diameter (IN) | 16.00 |

| Wire Diameter (IN) | 0.610 |

| Wire Spacing (IN) | 0.500 |

| Total Turns Each Side (Turns) | 8.0 |

| Each Primary Tapped At (Turns) | 4.625 |

| Inductance Each Side Calculated (mH) | 0.0169 |

| Diameter Each Side(IN) | 32 |

| Wire Length Each Side(FT) | 50 |

| Secondary Frequency Measured(kHZ) | 65.79 |

| Primary Capacitor (uF) | 0.1800 |

| Coil Form Diameter (IN) | 12.75 |

| Coil Winding Length (IN) | 60 |

| Wire Diameter (IN) | 0.043 |

| Wire Size (AWG) | 18 |

| Total Turns Each Side (Turns) | 1395 |

| Inductance Calculated(mH) | 116.37 |

| Inductance Measured Twin1(mH) | 114.7 |

| Inductance Measured Twin2(mH) | 116.0 |

| Medhurst K | 0.77 |

| Radius (IN) | 6.38 |

| Circumference (IN) | 40.06 |

| Wire Length (FT) | 4579.52 |

| Self-Capacitance (pF) | 24.89 |

Stopping by a construction company on the way home from work, I asked if they had any large diameter (12-in or larger) scrap water pipe. After some scrounging in the piles and handing over a crisp new $20 bill, a 12-foot length of dirty old 12.75-inch diameter SCH40 pipe was on its way to its new home bouncing around in the back of my truck. The Twins are conceived.

After some thought – but not too much, a call to Essex wire corporation results in the order for a tad bit of wire – 16,000+ feet to be approximate.

Took a half day vacation to drive down to Superior-Essex in Ft. Wayne and pick up a pallet of magnet wire - $250 for a 12-inch spool of GP/MR-200 weighing in at 80 lbs (but no shipping charges!)

|

|

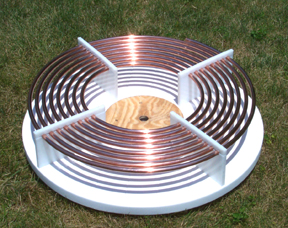

The winding apparatus.

How to wind a Tesla coil secondary

The "Twins"

Both "Twins" secondary coils are wound and epoxy coated. Time to start on the primary coils. Found some �-inch copper tubing about a year ago rummaging around an old relative’s garage – "Sure, go ahead and get that [stuff] out of here" they said. (that’s two 50-foot rolls still in the [original but slightly mouse-chewed-soggy-old] cardboard boxes.) The copper has been sitting around for a while (30-years?) and is slightly (understatement) discolored.

After trying anything and everything you can think of to clean the copper tubing, went out and bought some ZAP (sulfuric and muratic acid – nasty stuff) and a small kiddie-pool and soaked the copper until pink again (also took care of any bugs/snakes/who knows what might have been still lurking inside).

|

|

Before ZAP |

After ZAP |

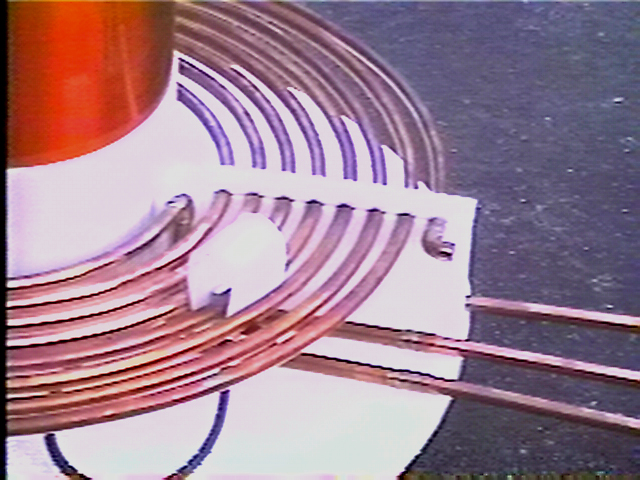

Design and build a cool clamp for tapping/tuning the primary coil.

|

|

Design |

Then Build |

Time to go shopping…..let's see....4 8-ft sections of 8-inch AL flex duct ($10 each), 2 8-ft sections of 4-inch AL flex duct ($6 each), 2 more rolls of AL tape ($6 each), 2 18-inch plastic flower pots ($8 each), 2 36-inch dia plastic tables ($40 each)

Time to build some toploads. Cover the flower pots with AL tape, and roll the ductwork around them...looks good....secure with some drywall screws, and there you have it - instant (almost) toploads!

More shopping....4 12-inch by 12-inch by 1/2-inch slabs of HDPE ($40) to make the primary coil stand-offs. Cut each in half on the table saw for 8 total, then drill 5/8-inch holes for tubing, then slice off the tops using the table saw.

|

|

Primary Coils "Snap-in" |

Then Bolt on the Tops |

Not much left to do - still may be able spark-up the Twins by tomorrow night?????

Didn't make it by the 4th....oh well....Twin One complete.

Primary One

Primary Taps

Twin One

Copyright 2003 - R. Scott CoppersmithAny Willful Violations Of This Site Subject To Severe Retribution |