How I build my 200BPS synchronous rotary spark gap

Well, as described at my BlueThunder page, I want to pump about 5kW through my setup. Even with only 15% losses in the gap (this value is only speculation!), this works out to up to 750W. So there has to be a significant cooling at the gap. Perhaps a good massive and heavy blown vacuum gap would have been sufficient. But hey, a rotary is way cooler!

If the static gap will not quench good enough (I bet it will as I have seen a standard muffin fan type RQ/RH cylindrical gap of a fellow coiler perform very well with my pigs), I'll build an additional asynchronous rotary spark gap (ASRSG) or even synchronous rotary spark gap (SRSG).

![]()

As described on Terry's website (hot-streamer.com/TeslaCoils/Misc/syncmot.zip), one has to grind some flats on the rotor of an ansynchronous motor to make it run synchronous. There have been some discussions on the TCML about how deep the flats should be made. Perhaps the flat is not the ideal shape, in January 2001, a new disussion about this started on the TCML.

A guy called David wrote on 1st. of June 2000 on the TCML ("economical rotary gap motor") that he acquired a bench grinder ("Black&Decker", 40$US) and modified it into a rotary gap. He reported that it functioned very well. It cames that just at the day I've read this post in the TML achrive, I found such a bench grinder (brand "parkside") in the supermarket below my flat - and it costed me only 29.90DM which was about 15$US at this time! A quick test of the thing showed a lousy torque (only 150W...), but a excellent bearings (no movement to any side possible as in most other motors like angle grinders)! Definitively an advantage for us coilers. The housing perhaps can be easily modified for holding the static electrodes. If I get promising results with the planned vacuum gap, the grinder remains a grinder, else it will be my first try to build an asynchronous rotary gap. I guess the 24 moths of guarantee will not be valid if I modify the bench grinder into a rotary ;-)) BTW, David gets 3m long arcs with his 10kVA pole pig and the described rotary - the dimensions of his garage are limiting the arc legth.

After reading more and more about rotary gaps, think I'll build a 200BPS synchronous RGS out of the bench grinder. Alternatively, I have an old motor out of a washing machine sitting around here (rpm, power?), which could also eventually be modified for an SRSG.

Of course I will use a proper set safety gap in parallel to the RSG. For fault current limiting purposes, I'll place two big (220W) 47Ohm resistors in series to it.

![]()

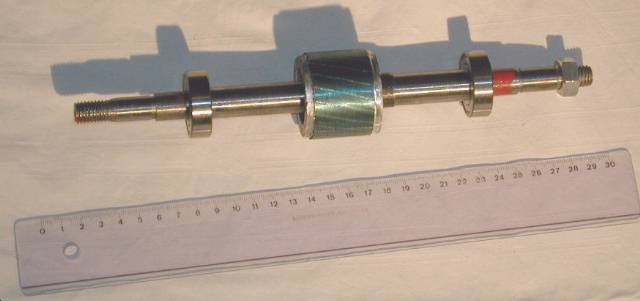

technical data of my bench grinder (double shafted motor):

Exploded view:

with 30cm-ruler for comparison:

the bearings (they are stamped with "XEZ 6202Z", anybody knows what this

means?):

where the flats will be grinded:

here in this shell sits the bearing:

the other side, view through the winding and poles:

Luckily, I got all the parts back together and the grinder works just like

before:

Excel-Sheet: tc/rgap/j.xls comparing the inertia of the rotary with the inertia of the bench grinder (=> how fast will the rotary come to speed)

| http://home.t-online.de/home/Stefan.Binder/

Flexigap:

Scheibe:

Schraube:

Geschwindigkeit: 310 km/h |

Original carborundum: 150mm diameter, 16.5mm thickness,

610g each.

Hubs: 54mm diameter, 170g all together.

Pertinax: 150mm diameter, 10mm thickness, 228g each / 200mm diameter,

10mm thickness, 405g each.

3000rpm, 2 flying electrodes, 4 fixed electrodes for 200BPS.

![]()

Material: Tungsten with Lanthanium,

diameter 8mm,

max. 4 rotating electrodes (length 50mm),

max. 6 static electrodes (length 25mm).

![]()

![]()

Phase shifter (electrically adjustable phase) for my SRSG (circuit

idea by John Freau, see TCML-archives of December2000 and

January2001):

The mechanical phase of the motor can be adjusted (electrically) by the use

of a variac (turn the knob) and a cap. Details will appear here as soon as

I have done some tests on my own...

The phase of one pair of fixed electrodes can be adjusted by rotating it on its wheel (for equal bangsize).

![]()