The ERO caps (MKP = selfhealing aluminized PP, 62nF, 1kVDC, 330VAC, 1500V/us

in series/parallel combination) that I use in Vitamini

still perform very well. I aquired some more of these caps and plan to use

them here in the 2"-system to reduce its size (height) and improve the

performance. I expect at least 50cm sparks (2 times the winding

length) with 540W input power and I'm even dreaming of getting up to

75cm (3 times the winding length). John Freau's formula

spark length = 5.8 * sqrt (power input)

/ 4th root ( BPS)

predicts 108cm, but this is for more common systems, I'm sure I'll get not

as much because my secondary diameter is far to small and I use not

enough inductance in the primary circuit.

Due to the good lifetime of these (ERO KP1836, 1000Vdc, 62nF) and other caps,

I decided to go for only 15 caps per string. I will use about 120%

(160%) of resocap size, so I will make

2 layers of up to 4x 15 caps each. Resocap size is approx. 18nF, so the optimum

120%-LTR value will be around 22nF.

Terry measured the ERO1845 and the result was an improvement from 40C/W

(based on lead spacing) down to 27.5C/W for them. Hopefully, this

improvement can be assumed for the ERO1836 with their 37.5mm lead spacing,

too. So the 33C/W might be reduced down to 22C/W. Terry' MMC-Calc says 14

caps per string (540VA at 9.5kV) with a static static gap. So I will try

the solution with 15 caps per string.

-

In Vitamini I have 20 caps in one string for 9450VAC. So I overstress the

caps there by 145%AC, 67%DC and 197%dU/dt.

-

Toni, a fellow coiler, stressed a string out of 20 caps with 15kVAC (212%AC

and guessed 99%DC and 62%dU/dt).

-

Reinhard (RWB) is also using these caps. His configuration is 67nF made out

of 13 strings with 12 caps each used together with a 7.5kVAC supply on his

8"-coil. He stressed them for 3 hours until I lost track on this (189%AC,

88%DC and 47%dU/dt) and reported no cap failure using these ERO-caps.

-

With the planned 15 caps in series for my 2"-system, I'll overstress them

193%AC, 90%DC and 150%dU/dt.

Compared to the old sw-caps, I will be able to reduce the total hight of

the 2"-system by about 16cm when using the new plastic caps (and additional

4.5cm by rearranging the filter board and static gap).

Update July 2005:

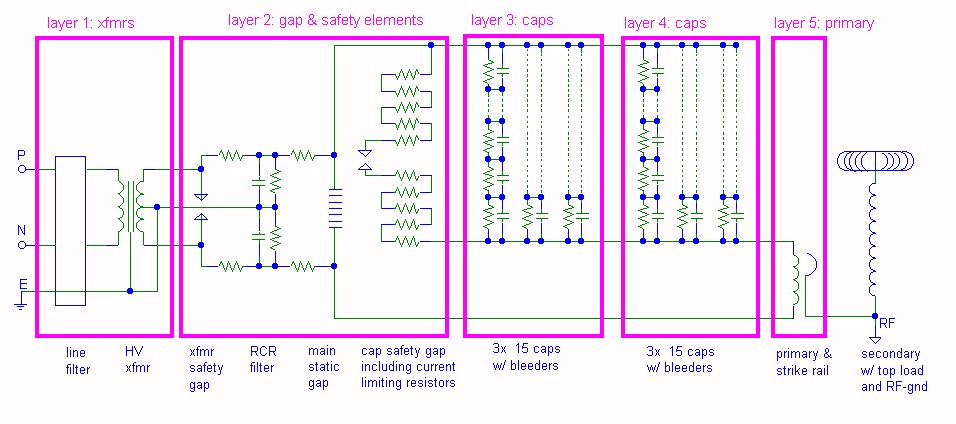

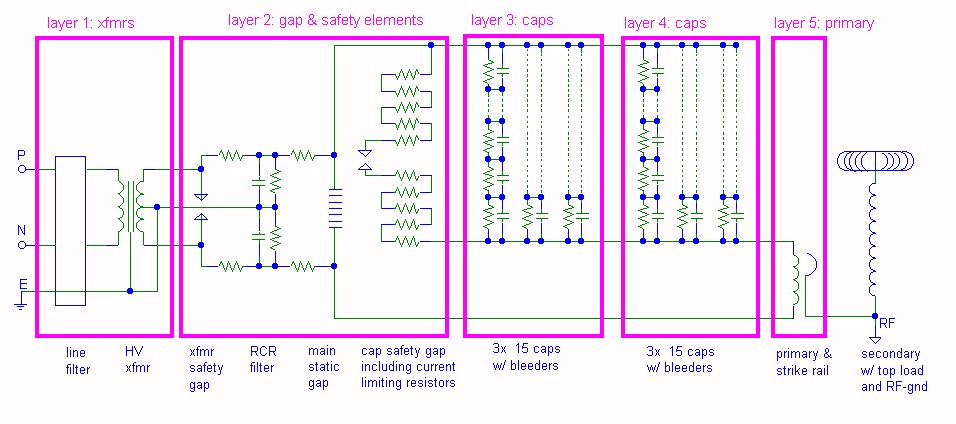

Wiring scheme:

A gap (~2mm wide) between the individual rows of caps has the advantage that

you can inspect the sidewalls of the caps in case some of them blew. Height

of the caps is approx. 2.7cm, I arranged them in two layers. I use an 1.8MegOhm

bleeding resistor across each cap. For increased cap lifetime, I added about

14Ohms in series to the safety gap (8x 1.8 Ohm) for reducing the voltage

risetime stress (=current) on the caps in case of saftey gap firing

down to a value near standard TC operation.

First test with the new MMC was done on 08.07.2005:

I did not use a couterpoise but connected the bottom of the secondary

only to the earth ground in my cellar (concrete floor not connected!),

so this was really a bad RF-gnd. The layers were not arranged on top

of each other in the housing but layed out just next to each other (=>

longer wires). I tested with 4x 15 caps (16nF) and the gap fired

pretty fast at approx. 100V. Using 2 additional packets of 2x 24

caps from the old setup in parallel gave me the 120% LTR value of 22nF.

I tapped 4.25 primary windings (approx. 4uH) and used an additional small

toroid T3 approx. 1.5cm above the top end of the

windings to suppress corona. I topped the whole thing with my toroid

T12 (6cm above T3). I calculated a frequency of 550kHz for this

setup. To suppress racing arcs (perhaps a sign of bad tuning - my old tap-clamp

was not easy to move around), I raised the secondary 2.5cm up for

loosing the coupling. Result was 30cm arc length to a grounded wire.

Still got some corona and racing arcs. I hope to improve this by proper tuning

after making a new clamp and by using a counterpoise as an improved

RF-gnd. Surprisingly, the arcs were longer when I shorted out one or

even two sections of my main spark gap. Measurement (only filterboard, no

caps) showed that the main gap will need 190V for 4 gaps,

220V for 5 gaps and 250V for 6 gaps. Nominal voltage here in germany

(without using a variac) is 230V. I've set the xfmr safety gap to fire

at 250V input voltage which is the maximum I get when cranking

the variac up as much as possible.

Energy per bang will be approx. 1.92J (compare this

with the 0.52J of the latest sw-cap arrangement with 9x 0.63nF or the 1.92J

with which I achieved 1.5m arcs using my 4"-TC with sw-caps in 1997!), peak

current in the primary around 670A (I have to recalculate this for the new

toroid I'll use).

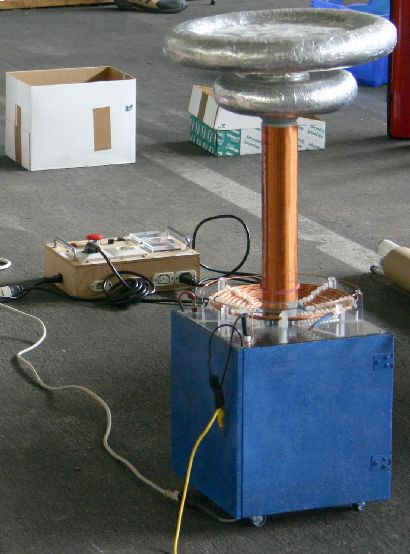

New secondary:

Since I used only 3 turns of the 9.4-turn primary, I decided

to wind a new secondary with approx. 4 times the inductance than the

old one. That will enable me to tap the primary at turn 8, leaving

a tuning range of 38% of inductnce using the full primary.

Since I had only a 0.22mm wire at hand (wanted to use 0.19mm

originally), I searched the DIY-store for a suitable tubing. I found

it in the rain piping section, where 53mm tubing is common instead of

the usual 50mm tubing in the plumbing section. The end caps which can

be found in the plumbing section fit perfectly into the 53mm tube of the

rain pipe section, so another problem was solved automatically! Furthermore,

I found an adapter piece for 50mm tubing to a metal pipe with approx.

75mm diameter, which fits perfectly into the 53mm tubing an allows a much

easier (more stable) placement of the toroids on top of the secondary.

To increase the diameter, I decided to slit an equal length of pipe and slide

it onto the other, filling the gap with epoxy glue (sanding it smooth afterwards

of course)

The design parameters for the new secondary are: 53mm-tubing with "sleeve"

for an outer diameter of approx. 58mm, winding length 11" (28mm), approx.

1240 turns (at 97% fill factor) of 0.22mm diameter enameled copper

wire.

I used two endcaps and removed the outer ring so that they can slide

into the tube. This way I can seal the tube and have still some bare tube

at the end where the mounting for the toroid can be placed

inside as well as another endcap screwed to the baseplate where

the primary resides. That way, I can mount all the pieces together very

quick when setting up at a new location (remember, this will be my transportable

and reday-to-fire TC) and in a sturdy way (don't want do damage

another toroid...)

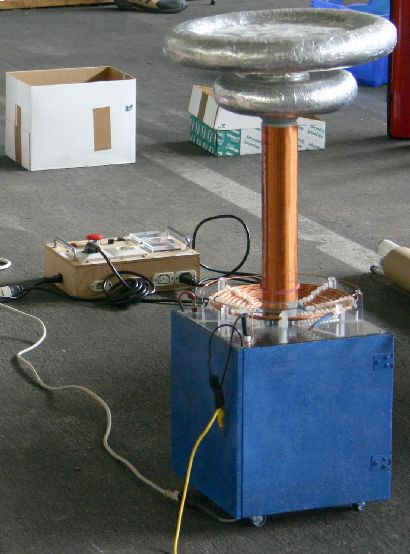

Results so far (20.07.05):

I got heavy racing arcs with the new secondary and had to reduce

the coupling compared to the old secondary. Despite this, I get

now 40cm with the new secondary (35cm with the old secondary in this setup)

at 22nF and approx. 540VA.

|