How I build my motor driven tuning coil...

![]() Sorry, this page is really

under construction at the moment. Things might be described not correctly

here...

Sorry, this page is really

under construction at the moment. Things might be described not correctly

here...

Tuning is a critical step in coiling. Critical because some elements of a Tesla coil system can be destroyed by doing it the wrong way.

And normally tuning is not easy: you'll fire the system up and try to notice the spark length, shut it off (and pull the plug!), re-tune (move the tap on the primary), fire it up again and try to remember the spark length of the run before, and do it all over and over again and again until the spark length is maximized....

But things can be much easier: by using a tuning coil, tuning can be done on-the-fly: online - while the system is sparking. You immediately can see if more or less turns will be optimum for the spark length.

My tuning coil will give me something 0-20uH additional inductance. So I can tune (+/-20% from optimum value) my 2"-TC with 3 turns, my 4"-TC with 4 turns and the BlueThunder (10"-TC) with the full 21 turns.

My tuning coil is buildt from flat copper wire (1x10mm2). It is 125mm long with 90mm mean diameter.

I'll use a 12VDC motor (with gear box) to turn the moving tap (consisting of 6 spring loaded contacts) of the tuning coil. Up to now I tested it with 12V, amperage is only up to 200mA.

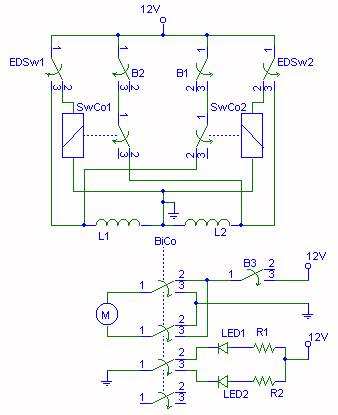

Detecting the end positions will be a bit tricky. I'll try to mount two levers which will be moved by the tap or better by the guided "block" at the axis so that the point of maximum inductance available can be adjusted. This levers will activate micro switches (EDSw1 and EDSw2) - of course well isolated from the voltage in the primary circuit. The isolated lever will have some mass and friction, so I perhaps have to load it by an additional spring to help the spring in the micro switch. The micro switches (EDSw1 and EDSw2) are intended to activate a bistable contactor (BiCo) which will change the direction of rotation. However the switches will activate the bistable contactor (BCo) not directly. There is a good reason to add an additional contactor (SwCo1 and SwCo2) for each end detection micro switch (EDSw1 and EDSw2). This is because of the way the tuning coil is operated. I plan to use three buttons here. One (B3) is to activate the motor which is only running while the button is pressed. With the other two buttons (B1 and B2) the direction of rotation can be preselected - each button (B1 and B2) will get its own indicator LED (LED1 and LED2) to show the current state of the bistable contactor (BiCo). One problem could arise: if the tuning coil is running into one of the end detection switches (EDSw1 and EDSw2) so that the switch is pressed, the belonging coil (L1 or L2) of the bistable contactor (BiCo) is activated. If this is not noticed by the operater and he will press the button for the other direction, both coils of the bistable contactor would be activated and the motor will not stop or even change direction so that the tuning coil could be damaged. Not good... Therefore, the two preselection buttons (B1 and B2) will be locked (= turned off = deactivated) by the two contactors SwCo1 and SwCo2 mentioned before.

Yes, I see that there is really a need for a circuit diagram:

The two contactors SwCo1 and SwCo2 can be omitted if I can install end detection switches with can switch two independent citcuits (1x closing + 1x opening)

![]() more to come...

more to come...