3.8kW (~10kVA xfmr input) Jacobs Ladder, 50cm arc path length!

The whole thing is designed to run off of a 16A fuse (slow blow type ;-) single phase 230V. For the first measurements, I used the two dry measurement xfmrs (voltage xfmrs, 100V/6kV), ballasted with my inductive ballast#2 (details can be found on my ballast page). Gap was initially set at 5mm for 15amps at 230V for the first try. But read on and see how I increased the power step by step!

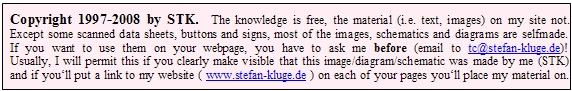

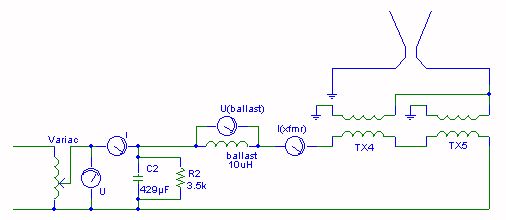

Wiring schematic (ballast value is wrong!):

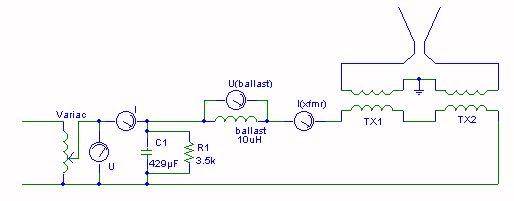

How to connect the parts on the board and protection of the windings with MOVs:

Writing with arcs ;-)

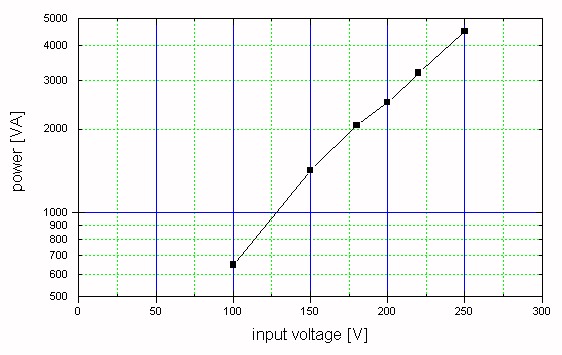

Measurements:

still without compensation caps:

| input voltage V |

input current A |

power (kVA) |

| 100 | 6,5 | 0,650 |

| 150 | 9,5 | 1,425 |

| 180 | 11,5 | 2,070 |

| 200 | 12,5 | 2,500 |

| 220 | 14,5 | 3,19 |

| 250 | 18 | 4,5 |

At 250V input voltage (18A), there are approx. 230V across the inductive ballast, that's 92%!

Compensation

caps:

![]() (11. August 2002)

(11. August 2002)

With the 5mm gap, my inductive ballast#2 deliveres approx. 15A at 230V as it should. The current should go down with the use of some compensation caps on the primary side. If the power factor is better then, the ballast gap can be opened up to get the current back to its original value with more power output on the HV side for a fatter arc.

For my 4"-TC at 2.6kVA, I used 171µF as compensation. The Jacobs Ladder is dedicated to run at 18(20)A at 230V, so I expect to use approx. 270µF for this setup (rough estimation, still to be verified).

For this measurement I bent the rails of the Jacobs ladder in such a way that the arc will remain steady at the end of the rails if it once reaches the top (only possible for short times since the rails will begin to melt very fast due to the very high power!). All the following measurements were done at 250V unless otherwise stated. For comparison, the first measurement was done without compensation caps and resulted in a current of 16.5A with the arc burning at the ends of the rails (the gap of the inductive ballast #2 was still set to 5mm).

The first thing I tried was to apply the 171µF (as set up in one of my famous cardboard boxes ;-) The current immediately dropped down to only 5.5A.

Now I successively opened up the gap of the ballast and here are the results:

| voltage V |

capacitance µF |

gap mm |

current A |

remark |

| 250 | 0 | 5 | 16,5 | appearent current 16.5A, with the active current (5.0A) of the next measurement, this works out to a power factor of 0.3 and a real power of only 1.35kW at 4.5kVA |

| 250 | 171 | 5 | 5,5 | appearent current 5.5A, reactive current 13.4A => active current

5.0A This works out to a power factor of 0.9! |

| 250 | 171 | 8 | 8,5 | |

| 250 | 171 | 13 | 12 | |

| 250 | 171 | open | 18 | |

| 250 | 230 | open | 15 | |

| 250 | 290 | open | 15 | |

| 230 | 260 (2*70+2*60) |

other ballast |

22 | now the limit is not the 15A max. amperage of ballast#2 but the 16A slow blow fuse ;-) |

For the inductive ballast#2 with the "gap" completely opened up, the optimum capacitance seems to be between 230µF and 290µF. As can be seen, I can't increase the current now with this ballast#2, because the 20mH in its open state are still to much. Therefore I'll take another one of my inductive ballasts, set to approx. 14mH for ~22A in Jacobs Ladder service at 230V (~260µF compensation capacitance needed, but this data is still to be verified!)

![]() (13. August 2002)

(13. August 2002)

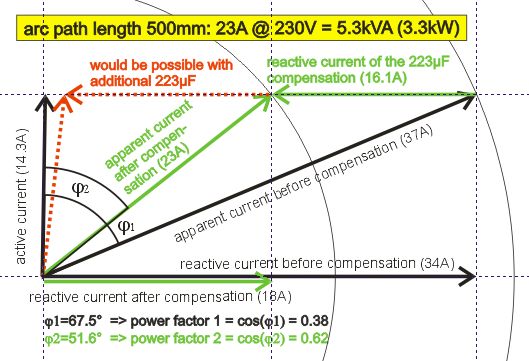

All the following measurements were done at 230V unless otherwise stated. Now I applied a bit more capacitance (for a total of 223µF which equals 16.1A reactive current at 230V) for compensation to my Jacobs Ladder and changed the ballast against a more powerful one (inductive ballast #1 set to 4mm gap). With the arc pinned to the narrow part of the rails (5mm gap) and 230V input, I got 30A input current and 43A to the xfmrs. Without compensation, the arrangement drew 47A input current. With the arc pinned to the top end of the rails (10cm gap, 50cm arc path length!) and 230V input, I got 23A input current and 37A to the xfmrs. Without compensation, the arrangement drew 37A input current.

| line voltage |

line current |

xfmr current |

capacitance | arc path length |

line kVA |

| 230V | 47A | - | 0µF | 5mm | 10.8 |

| 230V | 37A | - | 0µF | 500mm | 8.5 |

| 230V | 30A | 43A | 223µF | 5mm | 6.9 |

| 230V | 23A | 37A | 223µF | 500mm | 5.3 |

BTW, the max. input current of 43A is more than 4 times the current, the winding is specified for (only 10A ;-) And the xfmrs still stay cold (at least at the outside....) The average appearent power drawn from the line is approx. 6.4kVA (arc stays longer in the lower part of the rails where the gap is more narrow and the current higher) . Without compensation, it would draw ~10kVA average.

If I add a small inductive ballast (air core, 7mH) and remove the compensation, I get the current down to approx. 25A which is nearly the same as with the compensation and without the additional ballast. So the input kVA are the same, but the power factor is worse. One clearly can see that the arc is much brighter with compensation

![]() (14. August 2002)

(14. August 2002)

| line voltage |

line current |

xfmr current |

capacitance | arc path length |

line kVA |

remark |

| 230V | 23 | 37 | 223µF | 500mm | 5.3 | |

| 230V | 18 | 37 | 293µF | 500mm | 4.1 | |

| 230V | 15 | 38 | 363µF | 500mm | 3.5 | |

| 230V | 15 | 37 | 394µF | 500mm | 3.5 | |

| 230V | 15 | 38 | 429µF | 500mm | 3.5 | |

| 230V | 32 | n.m.* | 429µF | - | 7.4 | only caps |

| 230V | 30 | n.m.* | 429µF | - | 6.9 | caps + ballast + xfmrs without ignition |

| 230V | 17 | 45 | 429µF | 5mm | 3.9 | |

| 230V | 47 | 47 | 0µF | 5mm | 10.8 |

n.m.* = not measured

| optimized power factor calculation still missing... | |

| 5mm diagram | |

| 500mm diagram |

After playing for 45 minutes with about 3-5 minutes total runtime, the xfmrs got handwarm on the outside (30°C instead of 20°C).

Still have to find the big contactor to fire the beast up without the help of the big variac (to heavy to transport all those big iron cores...).

Conclusion:

For short runtimes at 230V (without any variac turned to 250V) and at 23-37A the output power was increased by factor 4 as compared to the initial setting. If I ever get the old watt meter running (ham fest buy without any documentation :-( I will measure how much real power now really is in those 5.3kVA, but I guess ~3.3kW (power factor 0.62). Oh, and yes, I'm still running off of a 16A fuse with the lights on. You just have to switch off the power before the fuse blows ;-))))

![]()

| Pics of the compensated Jacobs ladder (~5.8kW) coming soon! |

But I can already tell you that it's really worth to compensate a Jacobs

ladder and have more than 4 times the real current in the arc!

Now it is VERY impressive to look at!!!

It only needs 15A now, so I skipped the variac and simply use a contactor and a switch on a long cable to start the beast.

Daniel had a good idea on the small Teslathon we performed at his house on 17.08.2002: he advised to put both xfmrs in parallel on the secondary side to get more current into the arc (=> longer and fatter arc).

Wiring schematic (ballast value is wrong!) would be:

To assist ignition, a third electrode (helper electrode) could be put in the middle at the bottom end with an arc burning steadily between this third one and on of the main electrodes (rails), powerd by a small OBIT (thanks again to Julian for donating one to me!). Here you can see the bottom part of his Jacobs Ladder:

Stefan Binder used a helper electrode tied to one leg of the Jacobs ladder via a current limiting resistor and achieved good ignition down to 4kV (http://stefanbinder.privat.t-online.de/jacobs.htm).

Another idea of the day (by Daniel) was to place the compensation caps behind the inductive ballast so that the ballast only sees the reduced line current and not the full current going into the xfmrs. Daniel has tried it it success, I still have to try it.

Wiring schematic (ballast value is

wrong!):

One more possibility would be to place high voltage capacitors on the HV-side of the Jacobs Ladder like this guy did http://www.ctc-labs.de/phpBB2/viewtopic.php?t=601&postdays=0&postorder=asc&start=0

I aquired some new measurement xfmrs 20kV/SQR(3) to 100V/SQR(3). I want to use two of them in the configuration drawn just above. The setup will be heavy-duty for runtimes up to an hour continious to act as a background display in future events. The setup will consist of a wheeled box with all the components (compensation caps, xfmrs, ballast, metering etc.) and the two rails above. The rails will be held by big insulators against the top of the box and the backplane which extends up to 2.4m height. Eventually, even longer rails can be put in place (extending the backplane) for displaying at locations with a high enough ceiling (modular rails with flexible mounting).

Power level should be up to 10kVA on the rails with only 15A at 230V (1 phase) on the line side (that's the wonder of compensation!). When the ballast is moved to the line side of the compensation caps, the ballast current will drop by factor 2.5, therefore it will run a lot cooler, suitable for the long runtimes planned.

To make it simpler to transport in a small car, the backplane consists of some small parts which will be stacked and srewed to two 3x2 inch wood planks. "The iron" can be removed since I have to lift and carry all the parts on my own (long way from cellar to the car...). I'll connect heavy duty plugs to the xfmrs and ballast, so I won't have to fiddle around with thousands of screws connecting everything together "on the stage".

Coloured Flames:

You can add some colour to the flames by pasting some special salt onto the rails. Be careful not to drop the wet salt down onto the xfmr and wiring as salt is a very good conductor and will creep into each and every gap and pore of your wooden box turning the wood into a conductor as well! And do not add too much salt to the rails since the salt will melt dur to the high temperature of the arc and drop down turning the wood ... - you know what I mean.

Since I did not know all of the chemical wordings in english, some might still be german (or latin or what else...) but I think you get the clue:

| element (german) | element (english) | colour | salt (german) | salt (english) |

| Lithium | lithium | red | Lithium-Chlorid | lithium chloride |

| Natrium | sodium | yellow | Natrium-Chlorid (Kochsalz) | sodium chloride (table salt) |

| Kalium | potassium | violet / magenta / purple | Kalium-Chlorid Kalium-Carbonat (Pottasche) Kalium-Iodid |

potassium chloride (potash, K2CO3) potassium iodide |

| Strontium | strontium | red (carmine) | Strontium-Nitrat | Sr(NO3)2 |

| Barium | barium | green | Barium-Chlorid Barium-Nitrat |

barium chloride barium nitrate |

| Kalzium | calcium | brick-red | Kalzium-Chlorid Kalzium-Sulfat (Gips) |

calcium chloride calcium sulphate |

http://www.experimentalchemie.de/versuch-048.htm shows some images of coloured flames (the gas burner version).