Spark Gap:

This is my current synchronous rotary spark gap (srsg). It consists of a 7" diameter x 1/4" G-10 rotor. Attached to the rotor are four 5/16 - 18 x 3/4 brass bolts, which have been drilled down the center to accept 1-3/4" x 1/8" 2% thoriated tungsten electrodes. The bolt heads were drilled and tapped on three edges for 5-40 x 1/8 set screws to hold the electrodes in place. The four electrodes are connected by a 6" diameter x .016" thick copper ring. Below are the motor modifications

I used a 120 VAC 1/4 HP 1,725 rpm Emerson motor. I converted it to an 1,800 rpm salient pole synchronous motor by grinding four flats in the rotor.

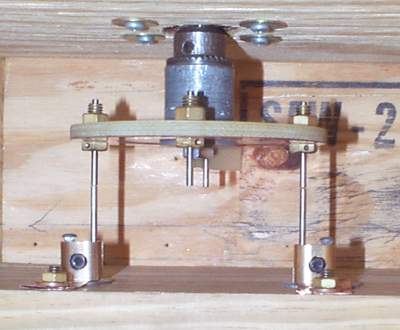

This is my small srsg. I have an 1,800 rpm sync motor which turns a 5" diameter x 1/4" G-10 rotor. Attached to the rotor are four 5/16 - 18 x 3/4 brass bolts, which have been drilled down the center to accept 1-3/4" x 1/8" 2% thoriated tungsten electrodes. The bolt heads were drilled and tapped on three edges for 5-40 x 1/8 set screws to hold the electrodes in place. The four electrodes are connected by a 5" diameter x .016" thick copper ring. The rotor is connected to the motor with a drill chuck.

This is my current Shop-Vac spark gap. It consists of two brass pipe fittings with copper studs soldered to them. The PVC fittings at the "tee" aren't glued, which allows gap adjustments. I've used it at up to 6kVA and it works great.

This is my leaf blower spark gap. It consists of two brass pipe fittings with copper studs soldered to them. The PVC fittings at the "tee" aren't glued, which allows gap adjustments. The blower is a dual speed permanent magnet motor leaf blower. My coil runs best at the highest setting, leading me to believe that I need more airflow with this gap. I later tried this same gap with a shop vac hooked up, instead of my blower. This seemed to increase performance, and is what I'm currently using for my pig.

This is my first spark gap. It consists of two rows of 10, 3/4" copper pipe fittings, mounted inside a section of 6" PVC pipe, giving me up to 18 gaps, with a total gap spacing of up to .63". A fan is mounted on top to assist in cooling and quenching.

| Controller | PSU | Cap | Gap | Primary | Secondary | Topload | Design (.doc) | Disasters | BigAss Coil |