High Voltage Power

Supply Units

Popular

Tesla Coil PSUs

Coilers use a wide variety of HV

PSUs. Here is a quick summary from smallest to largest.

Currently, this page will only go into detail on NSTs. More PSUs will be

covered here as I gain experience.

OBIT - oil burner ignition transformer,

puny

MOT - microwave oven transformer, typically voltage is a little low and you have

to make series/parallel connections

NST - neon sign transformer, ideal for coils with up to 5 ft arc output, easily

damaged by TC service

PT - potential transformer, requires ballast circuitry

PIG - distribution transformers like the ones you see on light poles.

Most coilers use 5-20KVA, 14KV units. Requires ballast circuitry

Neon

Sign Transformers (NST)

|

This is what you might find

at your local Sign Shop

I just got my hands on these 60 ma

NSTs. I found them at a small shop that makes Neon Signs and does sign repair in

general. From many months of searching I found that small shops are the best and

DON'T rely on phone calls.

There are basically 4 types of NSTs - you have 12KV models and 15KV models. Each

voltage comes in either 30ma or 60ma. Look for the 60ma models, but don't pass up

the 30's. Richard Quick has an excellent article on all aspects of NST usage.

I will look for it and link it here.

Richard

Quick Article on NSTs

This article covers depotting! I'm an order of magnitude more

agressive than Richard when It comes to increasing current output, but he is

trying to build a reliable device and I'm just playing around on the upper

limits of performance in the name of experimentation. Remember, many NSTs

die at their normal operating current (much less my 200+ ma!).

|

Enhancing

an NST

NSTs are current limited

transformers. This means that a NST will only produce a fixed amount of

current regardless of the output load. The current is limited by using

packs of metal shunts to "short circuit" the flux from the primary and

prevent it from intersecting the secondary. The current limit may be

adjusted by adding or removing individual leaves in these shunts. The

following pics are probably much more helpful than my ramblings...

All pics are

"clickable"

|

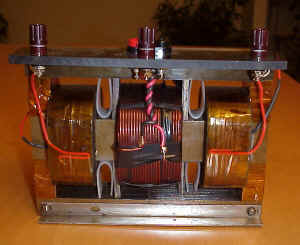

Final version

Final version of

the NST enhancement. Note the acrylic "C" shaped parts

that completely wrap around the secondaries. I also coated the edges

of the secondaries with about 2 coats of clear epoxy. Testing shows

that these additions, with the additional precaution of reducing my input

voltage to 120V, eliminates all of the nasty flashover and corona problems

that I was having.

|

|

Here is a Franceformer

12KV, 60ma unit after LOTS of work. The primary is the heavy gauge

coil in the center. The secondaries are wound on each side.

You can see the HV end of the secondaries going off to the banana binding

posts on the plexi and you can see the ground end of the secondaries

running out to a bolt on the E core.

The shunts are located on each side

of the primary and contain about 8 leaves each in this photo. I have

the shunts held in with some scraps of LDPE for testing and photos.

I need to investigate a more secure way to hold them in place for actual

TC use.

Note the insulative tape wound on

each side of the core nearest the secondary. I need to revise the

insulation to include the top and bottom of the core as well, occasionally

an arc will creep along the surface of the tape to the core! Note

this configuration is for photo/educational purposes only. Flashover

and corona were severe when operated in this configuration. See

"final version" photo above |

|

This is a top view

showing the primary connection, 2 HV connections, and the ground

connection in the center. Note that the core is composed of (2) E

shaped sections that are held together by 4 bolts on the corners.

There is no weld in the seam so you can easily seperate the halves and

remove the primary and secondaries. Note

this configuration is for photo/educational purposes only. Flashover

and corona were severe when operated in this configuration. See

"final version" photo above |

|

Close-up of the shunts. Note

this configuration is for photo/educational purposes only. Flashover

and corona were severe when operated in this configuration. See

"final version" photo above

|

Revision B (see

previous work below)

Although I couldn't get it to

arc over at 140V input open circuit, it displays some rather nasty flash-overs

when integrated with the RC filter and spark gap. The flash over usually

occurs when trying to ignite the gap. I coated both the inboard and

outboard edges of the NST secondary coils with epoxy. I made some acrylic

"C" shaped parts that wrap around the secondaries. The NST

originally had a tar paper version of this when it was potted.

I decided to stick with lower

voltages and run the NST at its rated input. I rewired my control box to

only supply 120 VAC. I adjusted the shunts in the NST to allow for about

200ma at the lower 116V input voltage. Between the lower voltages and

better insulation, I hope that cured the flash-over problem.

Here is the new test data

| Vin (volts) |

I in (amps) |

I out (ma) |

| 48 |

6.5 |

50 |

| 60 |

9 |

75 |

| 72 |

13.5 |

100 |

| 84 |

18.5 |

125 |

| 95 |

22 |

150 |

| 106 |

25 |

175 |

| 114 |

26.5 |

197 |

Vin was measured with a Wavetek 27XT. (I out) was

measured with a Simpson 200ma analog meter. (I in) was measured with the

cheap current meter on my control box. It's not very accurate but is handy

in showing a trend. My output current goes up to a solid 200ma and the

input current drops to 20.5A with the addition of the 135uF PFC cap.

Revision A (see

previous work below)

The original configuration

displayed occasional flash-over problems when running the variac at settings

above 120V. Had a problem with the NST HV bushings arcing to an angle

bracket used to support the plexi deck. I removed the angle bracket.

I removed the Kapton tape from the sides of the E core and replaced it with

electical tape and scraps of PE from a milk jug.

Preliminary testing of the de-potted NST

Voltage Input was 134-136VAC

from my controller

Input

Current |

Output

Current |

# of leaves

per shunt |

| 13.5A |

107ma |

14 |

| 17A |

128ma |

12 |

| 19A |

150ma |

10 |

| 22A |

175ma |

8 |

| 30++ A |

300ma |

0 |

Results of adding a 135uF PFC

capacitor to my ENST on the "8 leaves / shunt" setting

Note that the PFC cap almost halved the imput current while giving me slightly

more output current.

I believe that the gain in output current happened b/c the input voltage rose a

bit with the lower current demand.

Input

Current |

Output

Current |

PFC Value |

| 22 A |

175ma |

0 uF |

| 14.67A |

180ma |

135 uF |

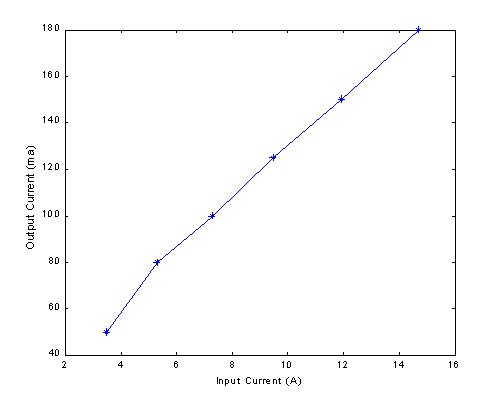

I wanted to check for

saturation of the NST core at higher power levels.

Saturation should be evidenced by a steep increase in input current with respect

to output current.

The NST has 8 leaves in each of the 4 shunts and is equipped with the 135uF PFC.

| I

(in) |

V (in) |

I (out), ma |

| 3.5 |

65 |

50 |

| 5.3 |

75 |

80 |

| 7.27 |

95 |

100 |

| 9.48 |

110 |

125 |

| 11.92 |

120 |

150 |

| 14.67 |

120 |

180 |

If you plot Output Current vs

Input Current, you get a nice linear relationship.

This suggests that saturation is not a problem at this power level.

[ Back to Tesla Main

| Back

to Ross Home ]